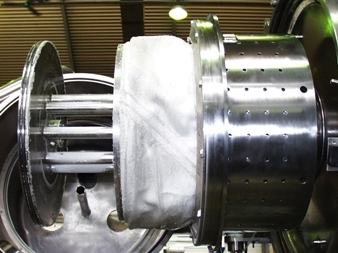

Horizontal Inverting Filter Centriges HT Back

Products

www.comicondor.com

www.comicondor.com

Description

Inverting Filter Centrifuge HT/GMP model guarantee a High Recovery Solid/Liquid Separation in a Single Environment Fine chemicals, activ pharmaceutical ingredients.

- Gentle - Solids discharge is performed by inverting the filter cloth and spinning the product off centrifugally. No discharge blade means that delicate crystals and macromolecules can be recovered without breakage.

- High Yield - Low Residual - High yield is achieved because the solids are discharged immediately by the inversion of the spinning filter and high centrifugal force. Because solids are discharged without the use of a blade or blowback, ultra-thin cakes can be processed efficiently.

- Improved CIP & Validation - There are three (3) moving parts (filter, platen and basket) inside the Inverting Filter Centrifuge. Crevices, seals and the additional surface area associated with the discharge blade, feed line, spray line and local control are eliminated.

- Drying Capability - Removal of bound moisture is performed with dry or heated gas at up to 6 barg differential pressure across the cake. ( HCS - Hyperbaric Centrifugation System )

Specifications

| Basket diameter | 300 - 1000 mm |

| Maximum basket load | 9 - 275 kg |

| Maximum basket speed | 3400 - 1400 RPM |

| G - factor x g | 1927 - 1100 G |

| Centrifuge weight | 700 - 8800 kg |